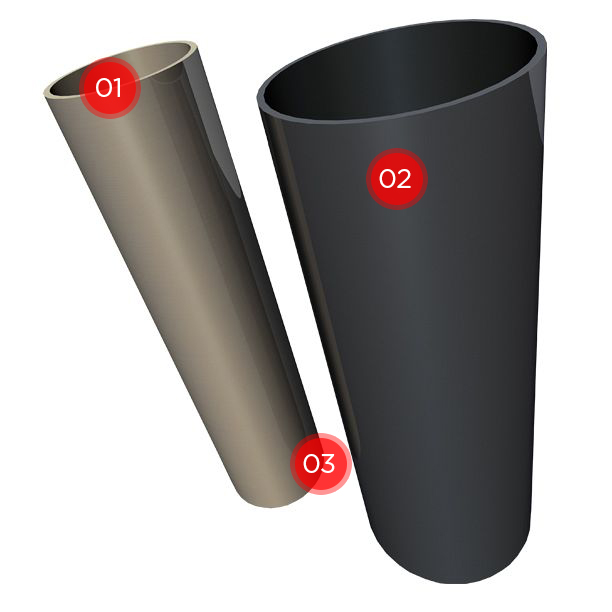

01. Aluminum

LEKI’s top poles use only high-strength aluminium shafts (as those used in aircraft construction) and refuse other, possibly more cost-effective material qualities. These are prepared and cured through a process specially developed by LEKI. Shafts processed this way deliver superior stability to withstand extreme conditions and applications. It is thus no surprise that LEKI’s high technology standards result in long-lasting and durable shafts and designs. LEKI quality is legendary!

02. Carbon

Carbon fibres result from complex carbonization processes of synthetic polymer fibres or organic substances. These processes yield a fibre mesh that is approximately eight times thinner than a human hair. In turn, carbon fibre shafts present an extremely high stiffness and bending capacity with a very low specific weight.

03. Innovative painting process

LEKI contributes to the protection of the atmosphere by using water-based paint systems and introducing emission-free powder varnish technology. The use of high-tech painting systems and sophisticated paint circulation solutions allows for the near-full recycling of all coating materials used. All processed coatings and printing inks are free of compounds containing heavy metals and harmful AZO dyes.

Wet paint method

Several layers of paint are applied to the prepared shafts. The surface is thereby sealed and protected.

Powder coating

Powder is applied in several layers by means of nozzles onto the shaft, baked at high temperatures in the oven, and then dried.

Anodic coating

In this coating technique, aluminium shafts undergo a chemical process. The result is a high-quality, super resistant, and virtually scratch-free surface.